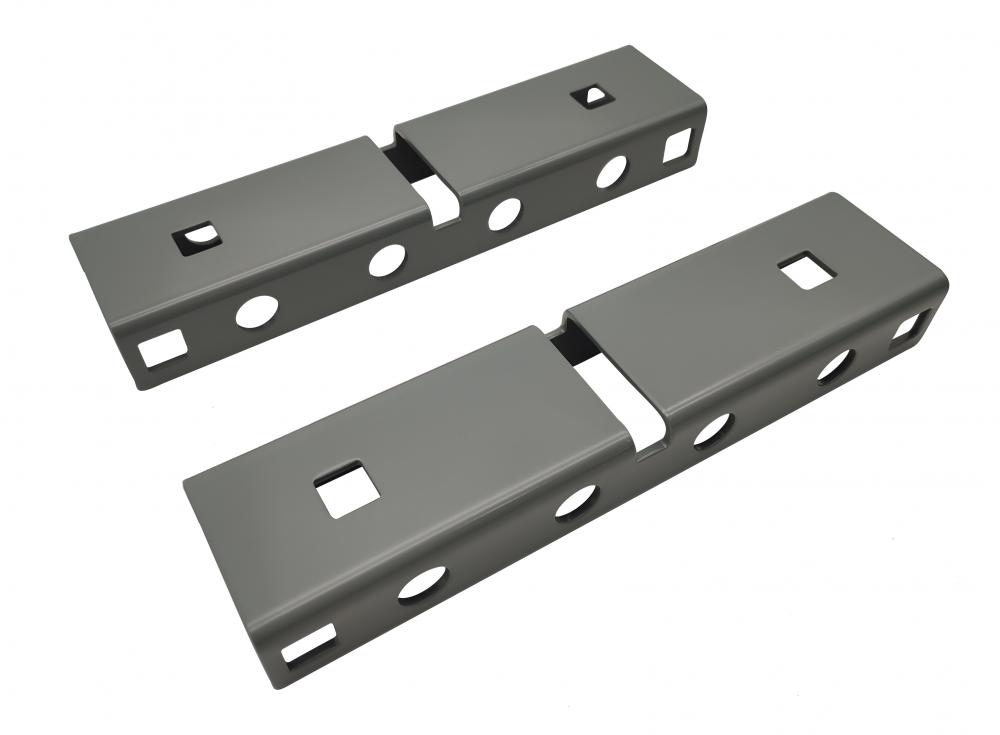

Sheet metal wire groove CNC solution

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,FCA |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

Select Language

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW,FCA |

| Transportation: | Ocean,Land,Air |

| Port: | Jiangmen,Guangzhou,Shenzhen |

Brand: OEM

Material: Other

Standard: En

Tolerance: +/-0.10mm

Surface Treatment: Powder Coated

Machining Method: Cnc Turning

Techniques: Cnc Welding

| Selling Units | : | Piece/Pieces |

| Package Type | : | Standard Export Packaing |

Aluminum alloy wire trough uses aluminum alloy one-step forming technology, extruded by large-tonnage hydraulic equipment, the thickness of the aluminum alloy sheet is 2mm, the upper and lower width of the aluminum wire trough is 110mm/180mm, and the thickness is 70mm/60mm. The design concept of electrical separation and strong and weak electrical separation is adopted. There are multiple cavities inside, which are used to install gas pipelines, strong current pipelines, and weak current pipelines. The surface is treated with electrostatic powder spraying technology. There are a variety of colors available. For selection, different modules can be sprayed according to user needs.

Sheet Metal wire groove CNC solution

Size: Customized (we can help size the right parts for your site)

Color: Grey/Black/White/Green and/or other specified color as agreed

Material: Cold Rolled Steel or specified material

Surface Treatment: Powder Coated and/or other specification

Process: Laser Cutting, Turret Punching, CNC Bending, Blasting, Polishing, Welding...

The Industrial Sheet Metal Parts/Chassis series of sheet metal produced by our company include: Metal Base Plate, Non-Standard Industrial Parts, and Wire Slot.

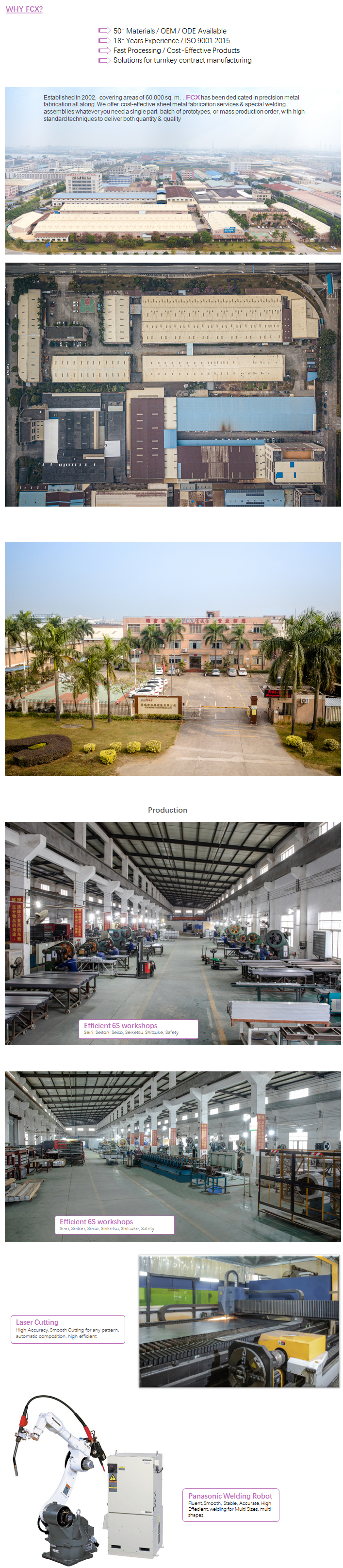

FCX also design and provide the solutions of an extensive range of non-standard parts as requesting with the features

NEMA/UL

Waterproof

Fire Rated

Pole/Tower/Wall Mount

Free Standing

Which for varied industry needs, covers Electrical Cable Cabinet, Traffic Systems, Weather Control Devices, Electrical Power Systems ... etc.

FCX's custom metal fabrication services offer subcontract metal manufacturing, engineering and assembly, from design, solutions to delivery, from simple metal enclosures, Display Racks, varied industrial Sheet Metal Parts, IT system Cabinets, Non-Standard Mini Warehouse to complex fully-integrated assemblies FCX has the technology and skills to deliver sheet metal fabrications and CNC machining services across all industry sectors, which include Telecom Equipments, Electrical Power System, Traffic Signal Controller Devices, etc. Capacity includes sheet metal machining, laser cutting, CNC punching, welding, powder coating, advanced assembly and more. And with impressive in-house facilities for subcontract sheet metal work, we can ensure speedy delivery and exceptional product quality.

Fabrication Capability

Feature Description & Facilities Allowable Capability Tolerance Material 50+ materials available, incl., Cold Rolled Steel, Carbon Steel, Stainless steel, Aluminum, Brass, Copper, alloy, etc. In shape:

plate, tube, Rod Processing CNC Laser Cutting, CNC Metal Bending & Forming, CNC Punching, Milling & Turning, Threading, Riveting, Drilling, Welding & Bonding, Blasting & Linishing, Casting, Powder Coating, Final & / or Partial Products Assembly Thickness: 0.5 ~ 12mm

Max. Length: 6000mm

Max. Width: 1500mm +/- 0.1mm

+/- 1º Surface Treatment Blasting, Polishing, Vacuum Plating, Powder Coating, Zinc Plate, Chrome Plating, etc Design & Solutions Software: Autocad, Pro E, CREO, Solidworks Logo Silk Print, Laser Marking, UV print, Multicolor pad printing Color Patone, Ral, RGB, CMYK

FAQ

1, Are you a trading Company or a Manufactuer?

Answer: We are a professional manufacturer with 18+ years experiences

2, Do you sell ready - made products?

Answer: No. We only customize NON-STANDARD parts as per requresting

3, How to get a quick quote?

Answer: for a quick quote, please kindly provide detailed spec. as possible,

include drawings, pictures, physical samples, quantity needed ..., etc.

4, Can I get a Sample?

Answer: yes, the samples can be prototyped shortly as per your spec. costly

5, What's your payment Terms?

Answer: 30% T/T in advance, balance paid before loading.

6, What's your lead time?

Answer: 7 days

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.